High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | I-suntop |

| Model Number: | I-90/120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | By negotiation |

| Packaging Details: | Plastic film+wooden box |

| Delivery Time: | Min.50working days |

| Payment Terms: | L/C,T/T |

| Supply Ability: | Up to different machine |

|

Detail Information |

|||

| Extrusion Material: | HDPE/MDPE | Line Speed: | Max.100m/min |

|---|---|---|---|

| Max.cores: | 288 | Application: | Manufacturing Of GYXTW, GYTA, GYTY53 Etc. |

| Warranty: | 12month | Voltage: | 80KVA 380V 50HZ AC 3 Phase |

| Highlight: | Fiber Optic Cable Jacketing Machine,Multi Strand Cable Jacketing Machine,100m/Min Cable Jacketing Machine |

||

Product Description

High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine

i-suntop fiber optic cable machine 20220228.pdf

1.Description for High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine:

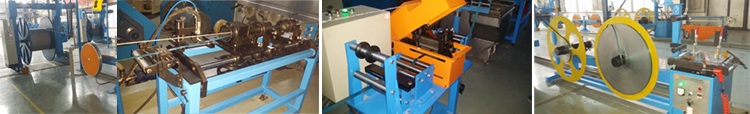

The jacketing machine is used to extrude sheathing for Normal optical cable and Micro optical cable. The line will be manufactured after the seller gets the order. 100% brand new.

1.1 Produce inner sheathing

1.2 Produce outer sheathing

1.3 The extruding materials: LDPE,MDPE,HDPE,HFFR,LSZH/PA12 and so on.

![]()

2.Advantage for High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine

A. The optical fiber pay-off is the motorzed pay-off device, the tension of the pay-off line is stable and reliable, and the tension is adjustable.

B. The extruder adopts special screw, which has good extrusion linearity and high extrusion efficiency.

C. International industrial computer technology control system with high degree of automation, it can be linked with MES, ERP systems, real time tracking and managing production..

D.The main control systems and components are international famous brands, and the production line has high stability and reliability.

3.Technical parameters of High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine:

|

Diameter of cable core |

5-25mm |

|

Diameter of loose tube |

1.5-3mm |

|

Diameter of cable |

5-35mm |

|

Thickness of cable wall |

1.0-3.0mm |

|

Line structure speed |

100m/min |

|

Line production speed |

80m/min(cable dia:10mm) |

|

Additional attenuation |

0.02dB/km (1310and 1550) |

|

Extruder output |

Max280kg/h |

4.Line Configuration for High Efficiency Good Quality Multi Strand Fiber Optic Cable Jacketing Machine:

4.1 800-1600 Portal type pay-off machine

4.2 Dancer with tension controller

4.3 Loose tube pay-off

4.4 Messenger wire pay-off

4.5 Aramid yarns stranding device

4.6 Dual Pad Metal Tape Pay-off

4.7 On-line seam welding device for Steel(Aluminum) tape

4.8 Metal Tape (steel-aluminum ) accumulator

4.9 Metal Tape (Steel-Aluminum) corrugating device

4.1.1 Metal Tape (Steel-Aluminum) longitudinal forming device

4.11. Cable jelly filling device

4.12 Water Blocking tape pay off

4.13 Rip Cord Pay-off

4.14 90/120×25 extruder

4.15 Cross head

4.16 Vacuum application unit

4.17 150KG Loader and hopper compound dryer

4.18 Hot-water tank and 4m movable hot-water trough

4.19 20m single-layer stainless steel cooling-water trough

4.20 Blow dryer device

4.22 25KV AC spark tester device

4.23 Hot foil length printer

4.24 Caterpillar 800kg

4.25 wheel type tension dancer for take-up

4.26 800-1600 Portal type take-up with traverse

4.27 IPC+PLC Electrical control system